Eliwell Controllers Support Bath College Refrigeration Students

Robert Burn, Business Development Director at Axair Refrigeration, visited the Refrigeration VRQ2 students at Bath College. Representing Alessandro Padrin from Eliwell Controllers by Schneider, Robert delivered a donation from Italy of a large number of specialist refrigeration electronic controllers that are required for the new course syllabus.

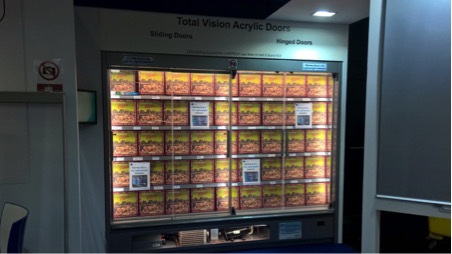

Robert gave a brief on the Eliwell EWPlus defrost controllers and Coldface Cold Room Panel and their uses in refrigeration applications. The refrigeration course students have recently begun their electrical module and will be using the controllers in their installations, like the one shown in the photo.

Simon Robinson, Refrigeration Lecturer at Bath College, has been in contact with Alessandro for a number of years now; “Alessandro never lets me down with donations of the latest controllers that are coming into the industry for the new up and coming engineers of tomorrow to use and favour. I feel without this type of generosity we would probably struggle to keep up with the changes in industry, but having this allows us to offer better content and courses at Bath College.”

Bath College offers vocational and academic courses in a wide range of subjects and helps students find a course to make sure they have the knowledge and skills for their chosen career. Working together with Eliwell and Axair Refrigeration, the College acts as a fantastic example of industry and education working together to provide up-to-date learning.

Bath College Refrigeration Course

The Refrigeration course is held in the Somer Valley Construction Skills Centre, where there is a specialist Refrigeration workshop. The Construction Centre caters for 500 students and apprentices studying bricklaying, construction, carpentry and stonemasonry, as well as plumbing, electrical installation and refrigeration.

As the largest provider of apprenticeships in Bath, the College also offers excellent opportunities for young people to earn and learn on the job. Find out more here.

Eliwell EWPlus Defrost Controllers

Find out more about our Eliwell EWPlus defrost controllers here or contact our team on sales@axair-refrigeration.co.uk or 01782 618 444.

More news >> Wellington’s Innovative ECR2 Refrigeration Motor Hits the 1 Million Milestone >>

Wellington’s Innovative ECR2 Refrigeration Motor Hits the 1 Million Milestone

Our supplier partner, Wellington Drive Technologies, is pleased to announce that its world-leading ECR2 motor has surpassed expectations, reaching one million units manufactured and sold in less than two years.

Our supplier partner, Wellington Drive Technologies, is pleased to announce that its world-leading ECR2 motor has surpassed expectations, reaching one million units manufactured and sold in less than two years.

The ECR2, a refrigeration fan motor, was launched to market at the end of 2016 as a quieter, more energy-efficient air flow solution. Since then, the ECR2 has been adopted by beverage cooler manufacturers, food and beverage brands, supermarket chains and medical refrigeration manufacturers globally looking for a smart, efficient and reliable motor to power their refrigeration fleet.

Wellington CEO, Greg Allen commented “This an amazing achievement, in just two years ECR2 has become our biggest selling product. Thanks to our talented Wellington team and our partner East West Manufacturing, all of whom, from design to distribution, made this product a success. This milestone reminds us how innovation and technology, focused on our customers, underpins our continued success.”

In its 2018 Half Year Results, Wellington reported that the company’s revenue growth was being driven by IoT and ECR2 motor product sales. This achievement demonstrates that the company’s new product strategy is working well and helping customers across many new markets.

Tony Nowell, Wellington’s Chairman commented, “Thank you to our customers and shareholders who have continued to support us and helped back ECR2. New products are the fuel to our continued growth and performance improvement. Historically Wellington was reliant on the bottle cooler EC motor market, but its strategic shift to also focus on new markets like supermarket display and food service is now being realised with products like the Wellington ECR2 motor.”

The Wellington ECR2 motor has been designed to offer a more sustainable refrigeration air flow solution and is capable of handling a wide range of commercial refrigeration applications. Its impressive range of advantages and features include:

- 5dBA quieter than other motors on the market, without compromising efficiency

- Multi-voltage capability, meaning customers can use one product in any country

- IP67 protection from dust and water ingress, meaning it is tested waterproof to one metre, essential in wet refrigeration applications (see more on IP ratings)

- Over-temperature capability which allows airflow to continue in the most extreme environmental conditions

- High Power Factor (up to 0.95), essential for larger supermarkets to ensure the lowest possible power consumption and thus utility bills

- ATEX compliant, suitable for use with flammable refrigerants such as hydrocarbon (see more on ATEX zones)

- Can be supplied using materials compatible with US and European food contact regulations, giving increased flexibility in food service applications

The Wellington ECR2 motor and other motors designed for refrigeration are available to request a quote online. Fill in your details and a member of our team will be in touch to help you find the best solution for your project.

For more innovative commercial refrigeration solutions, see our product page or contact us.

More news >> Comparing AC with EC Technology >>

Refrigeration – Comparing AC with EC Technology

Most refrigeration equipment manufacturers are by now aware of the requirements of the European ErP Directive on fan motors over 125W. This directive affects many condensing unit and chiller fans. Most evaporator fan motors fall below the 125W and are therefore not directly affected by the ErP Directive. However it is now possible to contribute to the “20% saving in energy by 2020” which lies at the heart of the directive and save significantly on the running cost of chilled and frozen food cabinets by introducing energy saving technology to the evaporator circuit.

Axair Fans has introduced new compact fans from Costech with EC motors which offer efficiencies comparable with similar DC motored fans, but without the need for a separate DC power supply.

| Fan part number | Airflow | Power input |

| A12B23HWBW00 | 148m³/h | 20W |

| E12B23HWBL00 (EC Model) | 198m³/h | 6.0W |

The 14W per fan higher input on the AC fan is passed directly into the refrigeration circuit as additional heat, so in a typical 6 fan case the thermal input from the fans is 84W less with the new EC fan. This is not however the end of the story, this additional heat has to be removed by the fridge circuit, in the case of a chilled cabinet with a COP of 2 this requires a further 42W of refrigeration or in a freezer cabinet with a COP of 1.2 an additional 70W.

Therefore the total energy saving on our typical 6 fan evaporator is now 126W for a chilled and 154W for a freezer cabinet. In most refrigerated cabinets the evaporator fans run continuously, except for a short period every 3-4 hours during the defrost cycle, so the fans are running for approximately 23 hours per day, 365 days per year, or 8395 hours per year. This means that the total energy savings per year with the EC motored fans will be 1058KWH for a chilled and 1293KWH for our freezer cabinet, which, at a typical fuel cost of 15p/KWH equates to £158.70 and £193.95 savings per case, per year.

Therefore the total energy saving on our typical 6 fan evaporator is now 126W for a chilled and 154W for a freezer cabinet. In most refrigerated cabinets the evaporator fans run continuously, except for a short period every 3-4 hours during the defrost cycle, so the fans are running for approximately 23 hours per day, 365 days per year, or 8395 hours per year. This means that the total energy savings per year with the EC motored fans will be 1058KWH for a chilled and 1293KWH for our freezer cabinet, which, at a typical fuel cost of 15p/KWH equates to £158.70 and £193.95 savings per case, per year.

This level of saving means a payback period for the small additional cost of the fans measured in weeks and more significantly £1000s saving on store energy costs, over £8’800.00 in a store with 25 each chilled and freezer cases, which goes straight on “the bottom line”.

Other benefits include 230V (or 115V) AC input requires no additional power supply, less wiring, possible Carbon Trust approval of products, increased reliability, no PSU to fail. For more information or technical advice contact Axair Fans.

More Food Processing News >>Food Processing & Manufacturing >>

Supplier Focus – Wellington Technology

This week we explore one of our well-known suppliers, Wellington. To understand how Axair Refrigeration can supply high-quality commercial refrigeration solutions.

Wellington’s biggest worldwide customer is Coca-Cola, with their motors powering point-of-sale fridges and vending machines in 45 countries. They also serve Walmart, Tesco and many other supermarkets and convenience stores.

Headquartered in Auckland, New Zealand, Wellington is dedicated to developing energy saving products that perform with more efficiency than many of the current components used in refrigeration and ventilation. Their 1,340 m² (14,423 sq ft) Technology Support Centre is home to a highly skilled and highly experienced team of engineers, specialising in electronically commutated motor (ECM)

software and technology.

A unique feature of Wellington motors is that they are manufactured from industrial plastics, rather than the expensive metals used in many traditional motors.This not only reduces the cost but also enhances performance and reliability. The manufacture of Wellington motors also uses far less material than conventional motors and wastage is kept to the absolute minimum.

As their official UK agent, we can now supply a range of products suitable for ventilation, refrigeration, heat recovery, and air conditioning. Utilising our relationship with Wellington, we can provide custom solutions and support special projects. As with all products from Axair, this is enforced by the product knowledge of our highly experienced team, backed by Wellington’s own engineers.

To find out more about the Wellington range and our expanding capabilities, Contact one of our Product Engineers today.

Carbon Refrigerants within Commercial Refrigeration

Carbon (CO2) refrigerants are changing the world of refrigeration as we know it, gradually replacing current Hydrofluorocarbon (HFC) and Hydrocarbon (HC) refrigerants in the market. HFC and HC refrigerants are currently the most commonly used refrigerants in refrigeration units.

HFC refrigerants contain Hydrogen, Florine and Carbon. Although HFC refrigerants have no ozone depletion potential, it does however act as a greenhouse gas with an average Global Warming Potential (GWP) of 2000. As a result, responsible use and equipment inspections are mandatory under the “F gas” regulations.

HC refrigerants are composed of just hydrogen and carbon and are considered a natural refrigerant with an improved average GWP of 3 and increased energy efficiency. HC refrigerants include Propane (R290), Isobutane (R600a) and Propylene (R1270). Its low GWP is a huge contributing factor to its popularity as a refrigerant in commercial refrigeration. In a typical supermarket 5 to 10 percent of refrigerants are expelled into the local atmosphere, using HC refrigerants annual gas emissions are reduced by tons each year.

Both refrigerants are highly flammable and are only allowed for use in units that fulfil the requirements stated in the latest revision of EN/IEC 60335-2-24. Although it may seem dangerous for commercial use preventative measures can be taken such as using ATEX compact axial fans such as Axair’s HEC Fan. Our specially designed fan has been created with the commercial refrigeration in mind and is IP68 and EC.

CO2 refrigerants, also known as R744, are economical, available in vast quantities and have a GWP of 1. They are also non-flammable and non-toxic but is however very high pressure. CO2 refrigerants are not a new thing and are very common in ship refrigeration plants, however the transition to CO2 in the commercial refrigeration market has just begun. Unfortunately unlike the HFC and HC refrigerants, CO2 refrigerants cannot be retrofitted. This is the only thing slowing the growth of CO2 refrigerants.

For more information about cooling for commercial refrigeration visit our applications page.

EC Fans V’s Refrigeration Evaporator Coils

Why are EC Fans an attractive alternative for refrigeration evaporator coils?

Electric motors operate by creating opposing magnetic fields in two locations, the fixed stator and moving rotor. In all electric motors, the primary magnetic field is produced by passing an electric current through a coil or coils.

Electric motors operate by creating opposing magnetic fields in two locations, the fixed stator and moving rotor. In all electric motors, the primary magnetic field is produced by passing an electric current through a coil or coils.

In an AC motor, the magnetic field in the rotor is created by induction across the air gap between the stator and the rotor and is inherently inefficient, creating what is known as ‘air losses’ which compound the already significant inefficiency of the ‘shaded pole motor’ used in most AC compact axial fans.

IN DC (and EC) motors, the second magnetic field is produced by permanent magnets, removing the losses created by induction across the air gap. A benefit of this is that the same power can be generated from a smaller coil, allowing a DC/EC motor to be smaller than its AC equivalent.

The First DC Motors

The first Dc motors had a rotating coil, surrounded by permanent magnets (the stator). To make the motor rotate requires the direction of the current (and therefore the magnetic field in the coil) to be reversed as the rotor turns. This is achieved with a commutator on the shaft; current is transferred to the coil by fixed carbon brushes, which require regular servicing and replacement, making ‘brushed’ motors inappropriate for most long-running applications.

Further Development

The development of low-cost electronics has allowed the replacement of carbon brushes by a circuit that senses the position of the permanent magnets in relation to the coil and which switches the direction of the current and hence magnetic field in the coil, to make the motor rotate. The development means that it is possible to make the coil, the stator and to put the permanent magnets into the rotor, simplifying the construction of the motor. Such motors are often described as ‘Brushless DC Motors’.

DC motors, of course, run on ‘direct current’, most commonly 12, 24 or 48 volts DC and this has to be provided by a power supply to convert from the main AC voltage. Even with modern electronics, such power supplies are substantial in size when providing enough power supply for several motors (as for the example on the evaporator of a refrigerated case) so the power supply becomes a separate unit which has to be located elsewhere in the cabinet.

Further developments in electronics have reduced the size of the components required to rectify and transform AC to DC such that it is now possible to integrate the power conversion onto the stator of the motor. Such motors with integrated power conversion have become commonly known as EC motors.

In the case of small, compact fans, as used on many refrigeration evaporator coils, the electronic has been added to the same frame size as the equivalent AC versions. This means that the fans can be changed from AC to EC without the need to add power supply or to make any changes to the case. Larger fans and motors, as used on condensing units, can incorporate the necessary electronics into a terminal box, usually as an extension of the stator flange on external rotor motors such as the EC axial fan from Rosenberg.

It is clear that the energy savings achieved by EC or DC motors are attractive for use in refrigeration because of the vastly reduced running costs of the motors, commonly 70% or more and the reduction of waste heat from the motors entering the fridge circuit (100w of waste heat from the fan motor requirements, typically, a further 50w of refrigeration to remove).

Some estimates suggest that 85% of the lifetime cost of a refrigerated display case is in the running costs, primarily electricity so it is clear that, with even a single case, the end user will make significant savings over the year and for users of multiple cases, like supermarkets, the saving on energy bills can be over £100,000 per year, simply by changing the evaporator fans from AC to EC. In most cases, the payback period for the additional cost of EC fans on an evaporator coil is less than one year.

More Product >> EC Compact Axial Fans >>

Axair Release ATEX EC IP68 Compact Axial Fan

ATEX EC Fan with IP68 Ingress Protection

Introducing our latest in product innovation, our ATEX EC compact axial fan. Axair Refrigeration holds innovation and customers at their core. With this is mind Axair Refrigeration listened to what both the market and their customers needed and after extensive market research Axair Refrigeration can announce that they are one of the few companies that can provide ATEX EC IP68 compact axial fans to their customers. Axair Refrigeration holds UK stock and can offer next day delivery.

Managing Director Grant Edwards commented

“Following the launch of Axair Refrigeration, our focus has been on delivering products that the market wants and needs. The Launch of our ATEX IP68 compact axial fan fills a gap in the market that is required in many potentially hazardous applications”.

Currently, the compact fan is available in the industry standard size of 120 x 120 x 38 in 3 speeds: High (3000 RPM), medium (2500 RPM) and Low (1700 RPM). This market innovation has an ATEX Rating of ll 3G ex llC Gc and is in keeping with the European ATEX directive known as ATEX 2014-34 EU. The directive is in place to ensure that certain levels of safety are established and that manufacturing standard are met. This will protect people against the risk of potential explosions due to explosive substances, especially hydrocarbon refrigerants. In this case, if a fan were to cause a spark it could possibly react with hazardous substances in the air causing an explosion with the potential to cause harm. ATEX fans are also known as spark proof fans, their inability to spark prevents the possibility of an explosion.

The fan is not only ATEX approved but EC. This means that as well as being safe it is energy efficient. EC is becoming increasingly popular in the air movement market and has become essential to the commercial refrigeration market. EC achieves its efficiency by combining AC and DC voltages. EC (electronically commutated) technology can save up to 80% on its AC counterpart. This is crucial for the ever stricter rules and regulations for energy efficiency in the commercial refrigeration market. This is just one example where our new fan is a crucial piece of equipment. Other applications include electronic cooling, lamp cooling, small heat exchangers, small condensers and evaporators, just to name a few. It is also IP68. This means that the compact axial fan is 100% dustproof and 100% watertight.

Product News >> Request A Quote for our ATEX EC Fans >>

Axair Partner with Sanden Environmental Solutions

Exciting Supplier Partner – Sanden Environmental Solutions

Exciting Supplier Partner – Sanden Environmental Solutions

Axair Refrigeration is thrilled to announce the extension of their product range with their exclusive supplier partnership with industry leaders Sanden. The supplier partnership will give Axair Refrigeration exclusive UK access to their innovative CO2 compressor technology.

Sanden, previously known for car compressors, have become key players in the commercial refrigeration market with being especially known for their CO2 technology. Sanden has worked hard and puts CO2 environmentally friendly technology at the forefront of their research and innovation. Products such as the CO2 horizontal compressor module is one example. Although CO2 modules are already used in newer refrigeration units what makes it so innovative is the fact is horizontal. The horizontal plugin compressor module is the first that can be installed in a stand-alone integral cabinet and its low profile means there is space for an extra shelf in the commercial refrigeration unit. The compressor can cater to a unit up to 12 feet and can save over 25% of energy versus its HFC140a equivalent. The unit, which debuted at the Euroshop show which took place in March 2017, has cooling capacities from 0.6kW to 3kW.

Business Development Manager Robert Burn commented:

“Axair Refrigeration, part of the Axair Group, is passionate about new technology and innovations especially those that continue to improve energy efficiency and help to meet stringent targets imposed upon our customers. The CO2 compressor module is ideal for the commercial refrigeration market. We look forward to developing our relationship with Sanden and further developing Axair Refrigeration.

Sanden environmental solutions have worked hard and have been determined to fill the gap that the market is shouting for: CO2 environmentally friendly solutions to commercial refrigeration. They are continuously developing new and innovative environmentally friendly solutions cater for the ever tighter environmental rules and regulations the refrigeration market faces.

The Axair Group encourages new and existing customers to contact them regarding any industrial or commercial requirements. For more information about Axair Refrigeration Sandon CO2 technology contact 07885 992 866.

Product News >> Request A Quote or Enquire About A Sanden Compressor >>